Ulstein has long shipbuilding traditions and specialises in building state-of-the-art newbuild vessels and takes on conversions, upgrades, retrofits, and repair assignments.

The ferries operate on a connection nearby and they needed maintenance work which required dry-docking.

"We are very pleased to be given this project by Fjord1. This is valuable work for us in a time where the dry dock is not in use", says the production manager at Ulstein Verft, May Kristin Myklebust.

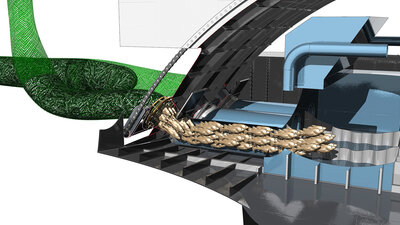

The three ferries need to raise the waterline. In the dry-dock they will undergo sandblasting, repaint of the water line, inspections of the valves, and other maintenance work after having been sailing for 2.5 years.

"We have the know-how and facilities, so we are more than happy to work on vessels throughout their lifecycle", the production manager points out.

"Ulstein is renowned for designing and building new vessels. This is something we will continue to do, but we also hope that the shipowners consider us when maintenance or conversion jobs need to be done", says May Kristin.

The compact shipyard has a covered dock hall, dry dock and all service workshops in close vicinity to carry out work in an efficient manner. This summer Ulstein Verft has conducted upgrade and repair work on several vessels and in the autumn Ulstein will start on a major project of converting two platform supply vessels to battery hybrid Emergency Response Rescue Vessels (ERRV).

Many of the upgrade projects demand close collaboration between the naval architects at Ulstein's design company and the yard's project team. Having in-house expertise is an advantage to secure cost-effectiveness and quick responses.

You can read more about our service- and aftermarket services here.