Crane lift and transport

Ulstein Verft specialises in heavy lift and transportation services. Our flexible equipment solves many lifting and transportation challenges on land and at sea.

Optimising time and resources

The Terex crane is a workhorse in our shipyard operations. Its impressive lifting capacity and versatile boom configurations can easily handle heavy loads up to 600 tonnes. Whether transferring, mobilising or demobilising ship components, containers, or other heavy equipment, the Terex crane provides the necessary strength and precision for safe and efficient lifting operations.

The Goldhofer SPMT multi-wheeler excels in transporting oversized and overweight cargo, and when combined with the Terex crane, we can provide a seamless and efficient workflow.

The seagoing barge is valuable for transporting the crane and/ or goods between locations.

We can offer our crane lift and transportation services along the Norwegian coast.

Mobile crane

CC2800-1 crawler crane

Max capacity 600 t

60 m arm: 14 m radius, lifting capacity 476 t

114 m arm: 14 m radius, lifting capacity 162 t

Video: 250t crane lift, the Terex CC2800-1 mobile crane being used for service dismantling of a quayside crane.

Multiwheeler transport

2 Goldhofer SPMT (self-propelled module transporters)

Heavy load transport: The two multiwheelers have a total capacity of 640 tonnes

The SPMTs are typically transported along the Norway coast on our 'Flex' barge and our mobile crane.

Seagoing barge 'Flex'

LOA 67 metres

Breadth 21 metres

Max capacity 3,697t

Video: Loading a 750-ton winch package at the I. P Huse winch production facilities use the Terex CC2800-1 crawler crane and the Flex barge.

Yard facilities

Ulstein Verft is a compact and complete shipyard to serve your needs.

Dry dock and dock hall

The controlled environment within a dry dock provides an optimal setting for ship construction and ship repair projects. Shielded from the elements, our workers can operate safely and efficiently, unfazed by inclement weather or turbulent waters. This climate-controlled haven ensures precise measurements and fittings and enhances the vessels' longevity and durability, reinforcing our commitment to delivering uncompromising quality.

Surface preparation and priming

We provide prepaint surface treatment for hulls and parts. Our dock hall offers a controlled indoor environment for the painting process.

Crane lift and transport

Ulstein Verft specialises in heavy lift and transportation services. Our flexible equipment solves many lifting and transportation challenges on land and at sea.

Mobilisation and demobilisation of equipment

At Ulstein Verft, we offer excellent logistics for effectively mobilising and demobilising equipment and tools for vessels such as subsea vessels, anchor-handling tug supply vessels and cable-laying vessels.

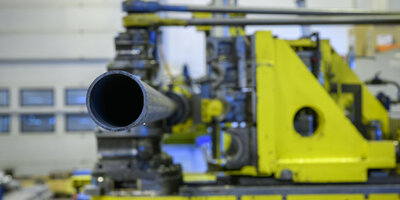

Pipe manufacturing

The pipe manufacturing department at Ulstein Verft is a supplier of high-quality pipes for new-build projects and aftermarket services.

Get in touch

Jostein Sørnes

- Description

- Section leader Heavy Lift/NDT operator

- Affiliation

- Ulstein Verft AS