Understanding the operational profile

Keywords: digitalisation, shipping, emissions, BlueBox, digital twin

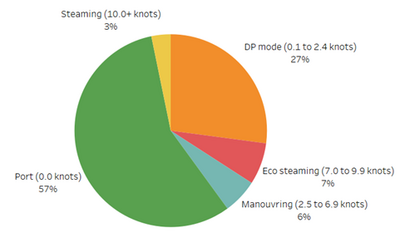

The operations of a platform supply vessel (PSV) under a long-term contract are primarily characterised by two operational modes, port and dynamic positioning (DP) operations. Figure 1 below represents a typical operational profile of a PSV in a long-term contract in the North Sea.

The call to reduce emissions and improve the effectiveness of vessel operations starts here. Understanding the operational profile of a vessel is essential to identify criticality and balance efforts towards improving the effectiveness of operations. Paradoxically this is not always the case, and some shipping operators are missing the full picture of how their vessels are being operated.

Reading the operational profile of a PSV, like the one in Figure 1, we can develop two initial propositions: i) shore connection can be effective to improve the environmental footprint of the vessel and reduce operational costs, and ii) a battery energy storage system can support greener, and more effective DP operations while keeping an equivalent level of redundancy and safety.

Shore connection - repaid in less than five years

A PSV spends nearly 5,000 hours a year running one of its engines, generating 200 kW. The vessel will commonly use its smallest generator set, typically on the 800 to 1,200 kW range. In other cases, the smallest engine is even larger, as the engine plant is composed of multiple equal engines of 1,500 to 2,500 kW. The resulting Specific Fuel oil Consumption (SFoC - [g/KWh]) is far from the nominal brake specific fuel consumption resulting from laboratory tests (or optimum SFoC). Over those 5,000 hours, the vessel will emit 1,000 tonnes of CO2, equivalent to 30% of the total emissions of one year. Hence, 1/3 of the total emissions of a PSV can be eliminated with the simple installation of a shore connection. And what is more interesting is that its repayment is just under 5 years. Of course, this makes sense of electricity from shore is "clean".

Related article: Zero-Emissions in port

A digital twin to evaluate battery investment

DP operations represent just half of the time the vessel spends at the port, however, the power consumption is more than quadruple, thus the potential for fuel savings and effectiveness improvements is still huge.

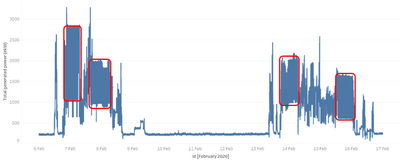

Real-time data retrieval and monitoring, together with simulation algorithms can support the quantification of battery savings before its actual installation onboard. With almost real-time vessel operational data - enabled by the BlueBox - and the observability of this information - enabled by Grafana - we can develop a Digital Twin of a battery installation. Why? To test initial propositions and evaluate the investment of a battery energy storage system will identify the most optimal SFoC that can be achieved. This can help to identify the right size and capacity of the battery, develop guidelines for its effective operation and be the basis for training programs for the crew, before the real assets are installed and ready for operation.

Figure 2 includes a screenshot of the power demand of a PSV during a 10-day operation. This information represents the basis for evaluation battery retrofit exercises in vessels in operation.

Would you like to know more?

Explore our featured articles below or get in touch.

We are eager to explore how digitalisation possibilities can improve the effectiveness of your vessel operations.