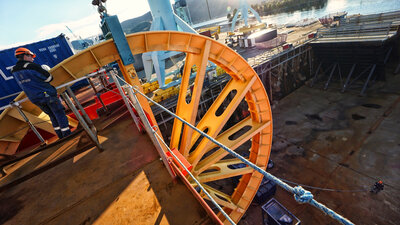

On 14 October, MAATS' & Marine Fabricators' installation team arrived on site to begin the installation, which kicked off with the two lay wheels being fitted at the stern. These wheels, in combination with the specially designed fairings, assist in guiding the cable in a controlled manner as it enters and exits the vessel. Following the lay wheels, final installation work is now being completed on the MAATS Tensioners and 75t SWL Capstan. The innovative vessel is constructed using the combined expertise of Nexans' extensive cable laying experience, Skipsteknisk's naval architecture know-how, Ulstein Verft's shipbuilding prowess, and MAATS' specialist engineering.

The vessel boasts a concentric, split basket 10,000Te carousel, dual cable lay capabilities, utilisation of separate Capstan or Tensioner firing lines, and the ability to complete operations in the most severe weather conditions anywhere in the world.