The thrusters are part of a major delivery from Brunvoll, which also includes two bow thrusters (3,100 kW), and a retractable azimuth unit of 3,000kW.

Parallell work tasks

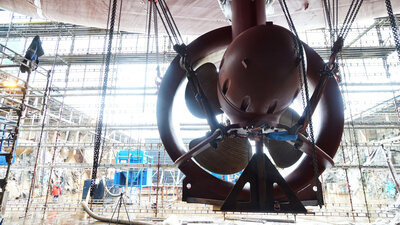

Multiple operations are going on at the same time during a ship construction newbuild project such as the 'Nexans Aurora'. The photo below shows the heave of one of the two tensioners, a Maats Tech delivery. The vessel is also currently being painted.