In February 2023, the Norwegian shipyard Ulstein Verft completed the extensive upgrade of the Windea Leibniz. After three months, the SOV vessel left the yard as a CSOV, with more accommodation, an adjustable pedestal starboard and a new pedestal aft. The purpose was to increase flexibility in operations, also geographically. Has it been a success?

Thorough does it when details count

Thorough engineering work and stability calculations are needed for such a comprehensive upgrade, which includes an increase in accommodation capacities, an adjustable pedestal starboard for the motion-compensating gangway to service the various TP heights in the North Sea, and a second pedestal in the aft for Baltic Sea operations.

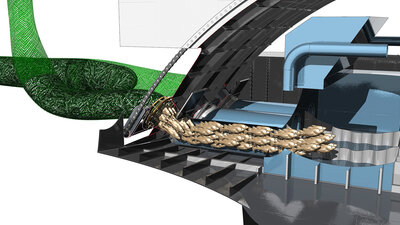

The walk-to-work gangway can be used alternately for both pedestals, working from two positions. It was initially positioned centrally and is now in the North Sea operations mode, resting in a cradle on the bridge roof, which therefore needed a structural upgrade. The area for the base of the starboard pedestal also needed to be strengthened. The lift has been adapted to service both positions of the gangway. The daughter craft needed repositioning, and lifeboats have been installed. Parts of the original pedestal were reused in the new pedestal aft to save costs, resources, and delivery time. The reconstruction of conference rooms, day rooms and changing/drying rooms was needed to increase the cabin capacity.

"Providing excellence in marine services"

The upgrade expands the operational range of the BSM-managed "Windea Leibniz" and makes her even more attractive for the offshore market.

"The significant and successful upgrade of the "Windea Leibniz" has been recognised by the industry. With all the new features in place, we can work in other segments than in wind farm maintenance projects. The entire team ashore and at sea alike, including myself, are delighted to be able to extend our field of operations. With this tailormade vessel, we're able to provide excellence in marine services to all kinds of industry demands today and in the future," says Rainer Müller, Master of the Windea Leibniz.

The upgrade expands the operational range of "Windea Leibniz" and makes her even more attractive for the offshore market.

Windea Leibniz 2.0 summary:

- Increase in accommodation capacities

The cabin capacity has been increased from 63 to 81 cabins. Windea Leibniz can now accommodate up to 85 technical staff for wind farms, service personnel and crew.

- Height-adjustable pedestal

The installation of a new height-adjustable pedestal for the motion-compensated gangway makes the vessel more flexible. The gangway can operate in a range between 17.5 metres and 23 metres height above the waterline when fully extended.

- More flexibility for Baltic Sea operations

The installation of a second pedestal at the stern enables the vessel to take on assignments also in the Baltic Sea, where service platforms are generally lower located than in the North Sea.

About the Windea Leibniz

The Windea Leibniz is an ULSTEIN SX175 design from Ulstein Design & Solutions AS and was delivered as a newbuild from Ulstein Verft in 2017. She features the X-STERN and X-BOW solutions for increased comfort and reduced noise and vibrations and is also X-BOW vessel number 100 from Ulstein Group.

Windea Leibniz is ready to support the planned offshore wind power expansion in Northern Europe. The vessel functions as a reliable and environmentally sound platform for wind farm operations and maintenance support, technician accommodation and transport, and the provision of safe and reliable access to offshore installations.

Stay competitive with aftermarket services from Ulstein Group.